SEO Blog

What Needle for Sewing a Rain Jacket?

What Needle for Sewing a Rain Jacket?

Sewing a rain jacket or any waterproof garment requires a specific approach due to the unique properties of waterproof fabrics. Selecting the correct needle and thread, understanding the fabric’s characteristics, and using appropriate sewing techniques are all crucial to achieving a durable and professional result. This comprehensive guide will help you navigate the complexities of sewing rain jackets, ensuring that your project turns out successfully.

Introduction

Why Choosing the Right Needle Matters for Sewing a Rain Jacket

Sewing a rain jacket involves working with waterproof materials that can be challenging to handle. The right needle is essential for preventing issues such as skipped stitches, fabric damage, and uneven seams. Using an inappropriate needle can lead to problems that may affect the garment’s functionality and appearance. By choosing the correct needle and thread, you can ensure that your rain jacket is not only waterproof but also well-constructed and comfortable to wear.

Overview of Waterproof Fabric

Waterproof fabrics are designed to repel water and keep you dry in adverse weather conditions. These materials often feature a coating or laminate that makes them resistant to water. Common types of waterproof fabrics used in rain jackets include nylon, polyester, and GORE-TEX. Each of these materials has specific properties that can influence how they interact with needles and threads. Understanding these properties will help you make informed choices when sewing your rain jacket.

Understanding Waterproof Fabrics

Types of Waterproof Fabrics for Rain Jackets

- Nylon: A lightweight and flexible fabric, nylon is often used in rain jackets due to its water-resistant properties. It is easy to work with but requires a needle that can handle its smooth surface without causing snags.

- Polyester: Known for its durability and water resistance, polyester is a popular choice for outdoor gear. It can withstand harsh conditions and is less likely to shrink or stretch.

- GORE-TEX: A high-performance fabric that offers superior waterproofing and breathability. GORE-TEX jackets are designed for extreme conditions and require specialized needles and threads to maintain their integrity.

Challenges in Sewing with Waterproof Fabrics

Sewing with waterproof fabrics presents several challenges:

- Slipperiness: Waterproof fabrics can be slippery, making them difficult to handle and sew accurately. Using a needle with a coating or a specialized presser foot can help manage this issue.

- Coating Issues: The waterproof coating on these fabrics can cause regular needles to struggle with penetration, leading to skipped stitches and uneven seams.

- Seam Sealing: Proper seam sealing is crucial to maintain the waterproof qualities of the fabric. Incorrect sealing can lead to water leakage, compromising the jacket’s effectiveness.

Choosing the Right Needle for Sewing Rain Jackets

Best Needle for Waterproof Fabric

When sewing waterproof fabrics, the following needle types are recommended:

- Ballpoint Needles: These needles are ideal for fabrics with a coating or those that are prone to damage. The rounded tip of a ballpoint needle pushes the fabric fibers aside rather than piercing them, which helps to avoid snags and damage.

- Universal Needles: Suitable for a variety of fabrics, universal needles can work well with lightweight waterproof materials. They offer a good balance of sharpness and flexibility.

- Heavy-Duty Needles: For thicker waterproof fabrics or rain gear that requires extra strength, heavy-duty needles are a must. These needles are designed to handle multiple layers and provide strong, durable seams.

Needle Type for Rain Gear

For specialized rain gear, consider:

- Twin Needles: Twin needles are useful for creating parallel seams or decorative stitching. They are particularly effective for reinforcing seams and adding a professional touch to your rain jacket.

- Triple Needles: If you need multiple rows of stitching for added durability, triple needles are a great choice. They provide extra strength and can be used for heavy-duty rain gear.

Sewing Needle Choices for Rain Jackets

Choosing the right needle size is crucial for a successful sewing project:

- Fine Needles: Use fine needles for lightweight waterproof fabrics such as thin nylon. They help create clean, precise stitches without causing damage.

- Heavy Needles: For thicker materials or rain jackets with multiple layers, opt for heavy needles. They are designed to handle the added bulk and provide strong, reliable seams.

Needle Size and Type

Selecting the Correct Needle Size for Waterproof Fabrics

The needle size you choose should correspond to the fabric weight:

- Size 70/10 or 80/12: These sizes are suitable for lightweight fabrics like thin nylon or polyester. They offer precision and control for delicate materials.

- Size 90/14 or 100/16: For heavier, more robust fabrics, such as thick nylon or multiple layers of waterproof material, these larger sizes provide the strength needed for clean stitching and seam durability.

Needle and Thread Compatibility for Raincoats

To achieve the best results, ensure that your needle size matches your thread choice:

- Cotton Threads: These are best paired with fine needles for lightweight fabrics. Cotton threads offer a natural look and feel but may not be as durable as synthetic options.

- Polyester Threads: Polyester threads are recommended for their strength and resistance to moisture. They work well with heavy-duty needles and provide durability for long-lasting seams.

Sewing Techniques for Waterproof Fabrics

Choosing the Right Thread for Sewing Rain Jackets

Selecting the right thread is essential for a successful project:

- Polyester Threads: Known for their strength and moisture resistance, polyester threads are ideal for waterproof fabrics. They provide durability and prevent seam failure.

- Nylon Threads: These threads offer excellent flexibility and durability, making them a good choice for heavy-duty rain jackets and outdoor gear.

Effective Stitching Techniques for Waterproof Materials

When sewing waterproof fabrics, use these stitching techniques:

- Straight Stitch: A basic and clean stitch that works well for most seams. It provides a simple and effective way to secure the fabric.

- Zigzag Stitch: This stitch helps to secure seams and allows for some stretch, which is useful for fabrics that need to accommodate movement.

Patterns for Sewing Raincoats

Choosing the right pattern can impact the ease of sewing and the final fit of the raincoat:

- Pre-Cut Patterns: Pre-cut patterns designed for waterproof fabrics simplify the sewing process. They often come with adjustments for needle size and seam allowances.

- Custom Patterns: For a personalized fit, adjust custom patterns to accommodate needle size and fabric thickness. This ensures that the final garment fits well and performs as expected.

Fabric Patterns and Seams

Seam Types for Waterproof Fabrics

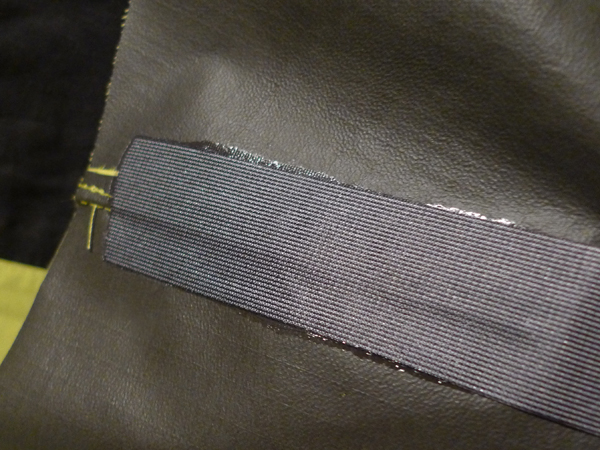

Choosing the right seam type is crucial for maintaining waterproof qualities:

- Flat-Felled Seams: These seams are ideal for durability and water resistance. They are strong and prevent water from seeping through.

- Bound Seams: Adding binding to seams provides extra protection against water leakage and enhances the garment’s durability.

Adjusting Patterns for Raincoats

When adjusting patterns for rain jackets:

- Modify Seams: Ensure that seam allowances and types are appropriate for the needle size and fabric thickness. This helps achieve a better fit and stronger seams.

- Add Seam Allowances: Increase seam allowances to accommodate different stitch types and ensure a proper fit.

Core Tools for Sewing Rain Jackets

Essential Sewing Tools for Waterproof Fabrics

To achieve the best results, use the following tools:

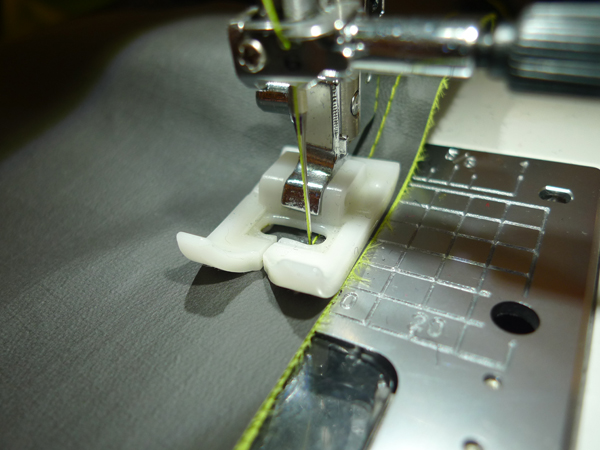

- Presser Feet: Choose a teflon or roller presser foot to manage slippery waterproof fabrics. These feet help guide the fabric smoothly and prevent sticking.

- Seam Sealers: Apply seam sealers to ensure that seams are fully waterproof. This additional step helps maintain the jacket’s effectiveness in keeping water out.

Choosing the Right Presser Foot for Waterproof Fabric

For sewing waterproof fabrics:

- Teflon Presser Feet: These feet are designed to glide over slippery materials without sticking, making them ideal for waterproof fabrics.

- Roller Presser Feet: Useful for feeding fabric smoothly, roller feet can handle multiple layers and help achieve clean stitches.

Additional Tips for Sewing Rain Jackets

Achieving Professional Results with Waterproof Fabrics

To ensure a professional finish:

- Use a Walking Foot: A walking foot helps to evenly feed layers of waterproof fabric, preventing shifting and puckering.

- Test Stitches: Always test your stitches on a fabric scrap before starting your project. This allows you to adjust settings and techniques for the best results.

Common Mistakes to Avoid When Sewing Raincoats

Avoid these common pitfalls:

- Using Incorrect Needles: Ensure that you select a needle suitable for the fabric weight and type. Incorrect needles can cause issues such as skipped stitches or fabric damage.

- Ignoring Fabric Layers: Pay attention to the number of fabric layers when choosing needle size and stitch type. This helps ensure that your seams are strong and durable.

Conclusion

Recap of Key Points for Choosing the Right Needle and Sewing Techniques

Choosing the right needle and thread is crucial for sewing a rain jacket. Consider the fabric type, needle size, and stitch type to ensure a durable and high-quality garment. Understanding these factors will help you achieve a professional finish and enhance the performance of your rain jacket.

Final Tips for Successful Sewing with Waterproof Fabrics

For the best outcome:

- Choose Quality Materials: Invest in high-quality waterproof fabrics, threads, and needles to ensure a successful project.

- Practice Techniques: Test your settings and techniques on fabric scraps before starting your main project. This helps you avoid common mistakes and achieve the best results.

Frequently Asked Questions (FAQ)

What type of needle is best for sewing waterproof fabric?

- Ballpoint needles or heavy-duty needles are recommended for sewing waterproof fabrics. Ballpoint needles prevent damage to the fabric’s coating, while heavy-duty needles handle thicker materials effectively.

How do I choose the right needle size for my rain jacket?

- Needle size should correspond to the fabric weight. Use finer needles (70/10 or 80/12) for lightweight fabrics and heavier needles (90/14 or 100/16) for thicker materials.

Can I use a regular sewing needle for raincoats?

- While some regular needles might work, it’s best to use needles specifically designed for waterproof fabrics to avoid issues like skipped stitches or fabric damage.

What thread should I use for sewing rain jackets?

- Polyester thread is ideal for waterproof fabrics due to its strength and moisture resistance. Nylon thread is also a good choice for its durability and flexibility.

How do I ensure my seams are waterproof?

- Use seam sealers and choose appropriate seam types, such as flat-felled or bound seams, to ensure that your rain jacket remains effective in keeping water out.

Skip to content

Skip to content